Types of Loads:-

We

will see in details study of load before going into depth of strength of

materials. It is very important to understand the different type of load in

strength of material (s o m), then only we well be able to calculate the stress

on the body.

Type

of load with respect to Time.

1.Static

load

a)Dead

load

b)Gradually

applied load

2.Dynamic

load

a)Impact

load

b)Fatigue

load

Static

Load

are such type of load whose

magnitude and direction remains constant for the entire periods of time. Where

Dynamic

Load

magnitude and direction are continuously changing. Those load which

increases gradually with respect to time is Gradually Applied Load

(G.A.P).

Impact

Load

is a load which is acting for short

interval of time, they are always a function of velocity. Impact load is

also known as Suddenly Applied Load or Instantaneous load.

Fatigue

load

are those load whose magnitude or

direction or both magnitude and direction changes with respect to time. These

load are repeatedly applied load with respect to time.

Fatigue

life

of a component is defined as number

of revolution that a component can undergoes before initiation of first crack. Fatigue

crack can be initiated first at stress concentration region, where the surface

is irregular or having some kind of defect.

Endurance

Limit

is the measure of fatigue life i.e. failure

stress of a material under completely reversed fatigue load condition. It

is obtained from S.N curve which is drawn using fatigue test reading. It gives

relation between stress and number of revolution.

It

is defined as maximum value of completely reversed bending stress that a

material can withstand for an infinite no. of cycle without initiation of

crack.

Based

on direction of load with respect to cross section.

Normal

load

which are acting perpendicular to the plane of cross section.

Shear

load

which are acting parallel to the plane of cross section.

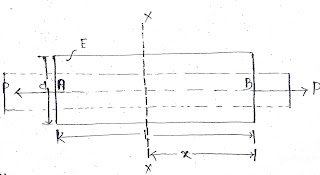

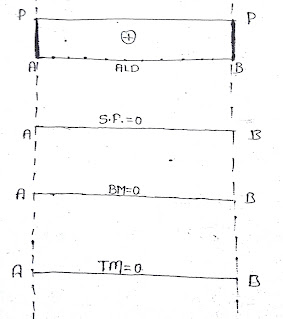

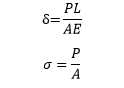

Axial

load

are such type of load which are acting along the longitudinal axis.

Eccentric axial load (ECC. Axial Load)

act parallel to the longitudinal axis.

Transverse Axial load (TSL)

are such type of

load which are acting perpendicular to the longitudinal axis.

Eccentric

transverse axial load (ECC. TSL)

act parallel to the longitudinal axis

Summery of loads:-

Sl. No.

|

Type of load

|

Plane of Cross Section

|

Longitudinal Axis

|

Centroidal Axis

|

1

|

Axial load

|

Perpendicular to the plane of

cross section

|

Along the longitudinal axis

|

Along the polar axis

|

2

|

ECC. Axial Load

|

Perpendicular to the plane of

cross section

|

Parallel to the longitudinal axis

|

Parallel to the polar axis

|

3

|

Transverse

Shear Load

|

Parallel to plane of cross section

|

Perpendicular to longitudinal and

passing through longitudinal axis

|

Perpendicular to poplar axis and

passes through centroid of that cross section

|

4

|

ECC. TSL

|

Parallel to plane of cross section

|

perpendicular to longitudinal but

away from longitudinal axis

|

Perpendicular to polar axis but

away from centroid axis of cross sections

|

5

|

Bending Couple

|

Perpendicular to the plane of

cross section

|

Along longitudinal al axis

|

Acts about either horizontal or

vertical to centroidal axis

|

6

|

Twisting Couple

|

Parallel to plane of cross section

|

Perpendicular to the longitudinal

axis

|

Act about the polar axis

|