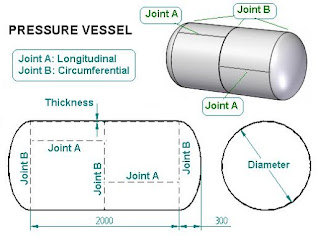

Thin walled Pressure vessel:-

What is pressure Vessel?

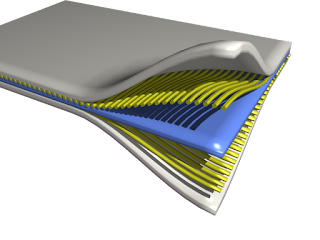

Pressure vessel is defined as closed cylindrical or spherical container which is designed to hold or to store fluids at pressure substantially different from ambient pressure.Classification of Pressure Vessel.

1.based on d/t ratio:-

1.Pressure vessel whose d/t ratio is greater than 20 units, such type of vessel is categorized to Thin walled pressure vessel (d/t

≥ 20).

Ex. Boiler shell, LPG cylinder

pressure cooker, storage tank

2. Pressure vessel whose d/t ratio is less than 20 units, such type is called as Thick walled pressure

vessel (d/t≤ 20).

Ex. Hydraulic cylinder, gun Barrel,

Storage tank

under high pressure

2. Based on Shape of shell

1. Cylindrical

pressure vessel

2.

Spherical pressure

vessel

DO comment !!!!!!

1.Why Spherical vessel better then cylindrical pressure vessel?

2.Which vessel we should used for safety purpose?

3.Which vessel we should used, keeping manufacturing cost in mind?

DO comment !!!!!!

1.Why Spherical vessel better then cylindrical pressure vessel?

2.Which vessel we should used for safety purpose?

3.Which vessel we should used, keeping manufacturing cost in mind?

Bursting of pressure vessel occurs circumferential.

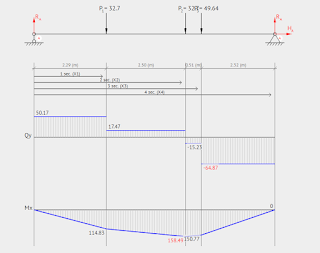

Condition-1

At particular

pressure, when longitudinal stress in thin walled pressure vessel is greater than ultimate strength, circumferential bursting occurs in pressure vessel.

σL> sut

FF

=

FR

FF= (π D2 P)/4-------------------------------i

FR= σLxπ𝐷x𝑡--------------------------ii

(π D2 P)/4 = σLxπ𝐷x𝑡

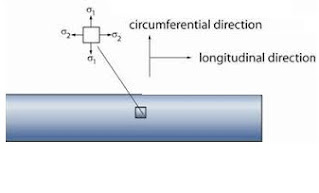

σL= σ2= σlongitudinal = pd/4t = σ1/2

Bursting of pressure vessel occurs longitudinally.

Condition-2

At particular pressure, when Hoops stress in thin walled pressure vessel is greater than ultimate strength, bursting occurs longitudinally in pressure vessel.

σh> sut

FF = 2xFR

FF= PxLxD-------------------------------i

FR= 2xσhxLxt--------------------------ii

PxLxD= 2xσhxLxt

σh = σ1 = σhoop = pd/2t

Thin pressure vessel can be considered bi axial state of stress (due to longitudinal stress).

σ1 = σhoop = pd/2t

σ2 = σlongitudinal = pd/4t = σ1/2

In plane τmax

=(σ1-σ2)/2 = pd/8t

Absolute τmax

=σ1/2 = pd/4tStrain stress

Major principal strain

ε1=εhoop= δD/D----------i

ε1= 1/E [σ1-μσ2]-----ii

σ2 = pd/4t = σ1/2

Equating i & ii

εh=δD/D=σ1/2E x[2-μ]

εh =pd/4tEx[2-μ]

Minor principal strain

ε2=ε longitudinal= δL/L----------i

ε2= 1/E [σ2-μσ1]-------------ii

σ2 = pd/4t = σ1/2

Equating i & ii

εL=δL/L=σ1/2E x[1-2μ]

εL = pd/4tEx[1-2μ]

Volumetric strain

δV/V=pd/4tEx[5-4μ]

Thickness of the shell

Safe condition of design (σ max)ind ≤(σt )per

σ hoop ≤(σt )per

σ hoop cylindrical=pd/2t ≤ (σt )per

σ hoop spherical=pd/4t ≤ (σt )per

Thin C.P.V

According to failure theory (MPST,MSST)

PD/2t= ≤(σt )per

t ≥PD/2(σt)per+corrosion

Added

Thin S.P.V

According to failure theory

(MPST,MSST,MDET)

PD/4t= ≤(σt )per

t ≥PD/4(σt)per+corrosion Added

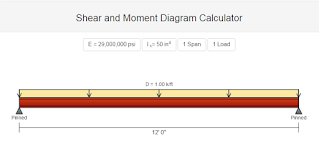

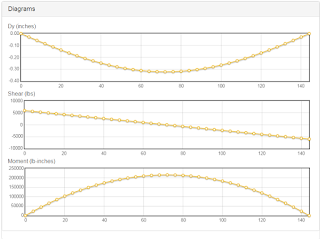

Refer Static Structure Analysis for thin Pressure Vessel in Ansys for better understanding .